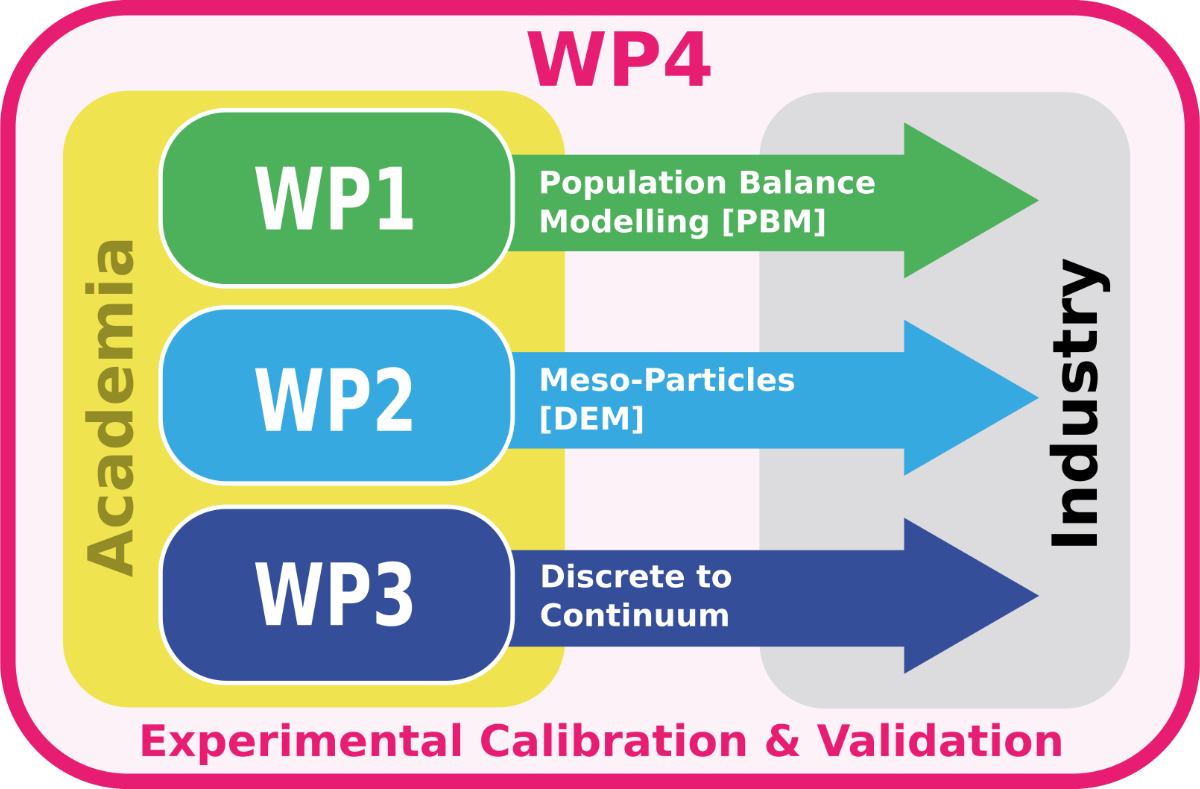

The overarching research goal of TUSAIL is to establish physics-based modelling, starting from characterising a small amount of a powder, to predict the behaviour of large industrial unit operations and processes via reliable upscaling methodologies and tools, bridging the gap between micro-mechanics and the industrial scale. To achieve this, four interlinked work packages are employed.

Particulate solids processes usually have a complex structure and consist of numerous separate sub-processes, connected to each other via mass and energy streams. While complex interconnections between different (sub-)processes can be efficiently dealt with by flowsheet models, individual sub-processes must be simulated at a much more detailed level by DEM to inform population balance modelling.

WP1 aims to provide PBM models that can be inserted into less detailed dynamic flowsheet simulations, which are a powerful approach for calculation of the time-dependent behaviour of complete large industrial processes and systems.

To address the enormous numbers of particles involved in large industrial systems, meso-scale methods simplify groups of primary particles as larger (meso) particles, significantly reducing the required computational effort. Most micro-scale information can be preserved; however, the calibration procedure and the limits of this approach are not well explored.

In fluid mechanics, working with dimensionless groups can be a viable upscaling approach, while using different meso-scale refinement/resolution will allow the limits of such methods to be understood. Eventually, the calibrated meso-scale models can be used to improve the design and optimise the operation of industrial-scale processes.

Multi-scale, particle-based, continuum theoretical constitutive models can be derived from DEM and DEM+CFD simulations. Great advances have been made in constitutive modelling in recent years, e.g., incorporating micro-structure tensors (anisotropy or rotations) based on DEM data or particle kinematics via relevant dimensionless groups. However, there is still no best-practice guideline for parameter estimation, calibration and validation.

WP3 will further develop and establish upscaling via continuum theory as a useful, predictive tool for industry.

The multi-scale nature of particulate systems and processes means that no single existing experiment, theory or numerical method alone can cover this wide range of scales and regimes.

WP4 is overarching the other scientific work packages: experiments on element tests for calibration and on lab-scale and pilot experiments for validation will be designed, carried out and used for WPs 1-3. WP4 will thus provide the experimental database for BOTH model calibration and simulation validation of the new innovative methods developed in WPs 1-3.