Oguzhan Erken, Jin Y. Ooi, Prashant Gupta, Luigi Capozzi & Kevin Hanley

Powder Technology 437; 119561. DOI: 10.1016/j.powtec.2024.119561

(2024)

Share On:

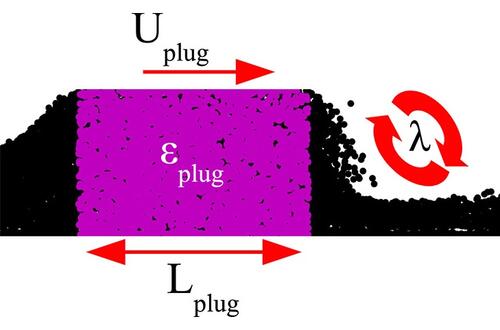

Even though particle shape tends to have a major influence on the bulk behaviour of a granular system, perfectly spherical particles are often used in numerical simulations. In this study, we examine the plug flow of ellipsoidal particles in dense phase horizontal pneumatic conveying within a rigid and cylindrical pipe with periodic boundaries in the axial direction. We use coupled Computational Fluid Dynamics (CFD) – Discrete Element Method (DEM) simulations to investigate the effect of particle shape on four plug characteristics: velocity, length, porosity, and particle exchange rate with the stationary bed. Both ellipsoidal and spherical particles are used, and the parameters varied are the particle size, aspect ratio, pressure gradient, particle–particle and particle–wall sliding and rolling friction coefficients, and coefficients of restitution. The steady state characteristics of plugs composed of spherical particles are distinctly different from those composed of ellipsoidal particles. Certain parameters, including the particle–wall rolling friction and restitution coefficients, have minimal impact on the steady state plug characteristics. The present study also suggests that introducing interparticle rolling friction for perfectly spherical particles can achieve the velocity and length appropriate for plugs composed of ellipsoidal particles, although differences in dynamics may persist. Overall, this comprehensive analysis offers valuable insights into plug flow behaviour with non-spherical particles, aiding in the efficient modelling and design of pneumatic conveying systems.