Yeswanth Sai Tanneru, Jan Henrik Finke, Carsten Schilde, Yogesh M. Harshe & Arno Kwade.

Powder Technology 444; 120060. DOI: 10.1016/j.powtec.2024.120060

(2024)

Share On:

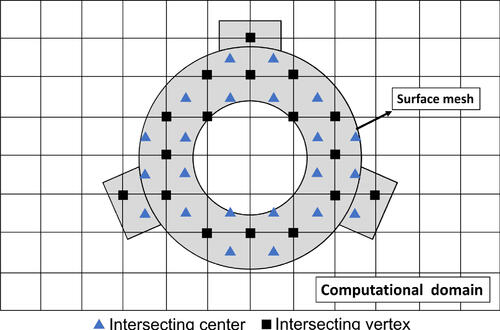

Qualitative description of stressing energies between grinding beads/media in wet stirred media mills at different operation settings could provide a comprehensive understanding of the process parameter influence. In the current work, a modeling approach for wet stirred media mills is described, employing a coupled CFD-DEM framework. This study employs an immersed boundary methodology to emulate the pin-type stirrer rotation in CFD and utilizes a hydrodynamic lubrication force to model the squeezing out and sucking in of fluid between two grinding bead surfaces. The results indicate the influence of process parameters such as the stirrer rotation speed, bead diameter, and bead filling degree. Key findings include the necessity of coupled CFD-DEM with lubrication (i.e., comparison of results from DEM, and coupled CFD-DEM simulations). Dependence of system dynamics on the fluid properties is numerically analyzed using the properties of water–glycerol mixtures.