University of Edinburgh [ 24 months ]

Procter & Gamble Technical Centres Ltd [ 12 months ]

Turn on Javascript!

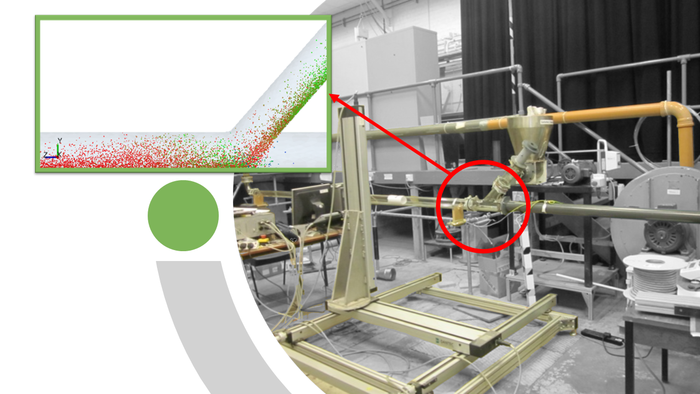

I am Oguzhan Erken and come from Turkey. I obtained my BSc in Mechanical Engineering at Bogazici University. Then, I finished my MSc at Koc University Mechanical Engineering Department under supervision of Prof. Dr. Metin Muradoglu. My Master’s project was about computational modelling of airway closure, and I used a Direct Numerical Method, called Front Tracking Method in this project (more details can be found here in my Google Scholar Page). Now, I am a part of TUSAIL and working on usage of meso-scale particles in pneumatic conveying. I am currently at The University of Edinburgh, and I will be at Procter & Gamble in the last year of my project. My supervisors are Dr. Kevin Hanley and Prof. Jin Ooi from The University of Edinburgh, and Dr. Prashant Gupta from Procter & Gamble.

The aim of my project is to reduce the computational expense of CFD–DEM simulations of pneumatic conveying by developing a quantitative and predictive simulation method using meso-scale particles, correctly accounting for the fundamental gas–solid interactions. For this purpose, experimental data from lab- and pilot-scale pneumatic conveyors will be used to derive appropriate scaling relations that will be incorporated into the simulation codes. The desired output of the project is a practically useful approach to design and optimise pneumatic conveyors for a broad range of industrial applications at an acceptable computational cost.

Pneumatic conveying is widely used for transporting granular materials. DEM–CFD provides a multi-scale hybrid approach to simulate such systems but is very computationally expensive. The scientific challenge is to take the fundamental fluid–solid interactions into account to develop a quantitative, predictive method for conveying using upscaled particles, enabling faster simulations and creating a practically useful tool to design and optimise pneumatic conveyors.

Oguzhan Erken, Jin Y. Ooi, Prashant Gupta, Luigi Capozzi & Kevin Hanley (2024), Parameters affecting plug characteristics in dense phase pneumatic conveying of ellipsoidal particles Powder Technology, 437; 119561. https://doi.org/10.1016/j.powtec.2024.119561