University of Edinburgh [ 12 months ]

Johnson Matthey [ 24 months ]

Turn on Javascript!

Turn on Javascript!

Turn on Javascript!

Turn on Javascript!

Turn on Javascript!

I'm Afshin Taghizadeh, and I'm originally from Iran. At the University of Mazandaran, I earned a BSc in Chemical Engineering. Then, under the guidance of Prof. Seyed Hasan Hashemabadi, I completed my MSc at Iran University of Science and Technology in the Chemical, Petroleum and Gas Engineering Department. CFD and experimental investigation of the waste tire pyrolysis in rotating drum was the subject of my master thesis (more details can be found here in my Google Scholar page). Having finished my study, I started my career as a process engineer in different area, including the oil and gas, and food sectors. I gained valuable experience while working in the industry, and after 3.5 years I made the decision to pursue my study as a PhD candidate. Now, I am a part of TUSAIL and working on Multi-scale modelling of particle agglomeration through sintering. This project is in collaboration between the University of Edinburgh and Johnson-Matthey. My supervisors are Prof. Jin Ooi and Dr. Kevin Hanley from the University of Edinburgh, and Dr. Vincenzino Vivacqua and Dr. Darren Gobby from Johnson-Matthey.

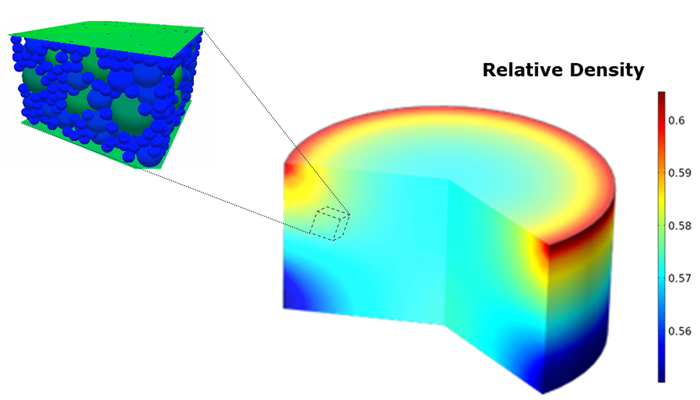

The scientific aim of my project is to develop a multi-scale approach to study the complex phenomena in the agglomeration process of particulates through solid state sintering. Solid state sintering is a key technology in the development of new advanced materials such as ceramics, and it has a wide range of applications. Controlling the shrinkage and microstructural evolution during solid state sintering is crucial to the dimensional accuracy and properties of the products.

This project develops a multi-scale approach to study the complex micromechanical phenomena in the agglomeration process of particulates through sintering – important in the ceramic and other industries. The micro-mechanical models using DEM will predict agglomeration, grain size/pore distributions, anisotropy and inform the development of population balance models and continuum constitutive models using the finite element method (FEM). X-ray microtomography will be used for validation of these models.