Hamburg University of Technology [ 24 months ]

Société des Produits Nestlé S.A. [ 12 months ]

Turn on Javascript!

Turn on Javascript!

Turn on Javascript!

Turn on Javascript!

Turn on Javascript!

I am Marina Latino, from Cosenza, Italy. I earned my Bachelor’s degree in Food engineering at University of Calabria (Italy) with a study path focused on the subjects of chemical engineering and also with attention to Innovation in the Food Industry, Industrial Processes and Technologies and Optimization.

Now I am a Master’s student of the course of Chemical Engineering (Process path) at the University of Calabria. In the latest years, during my master’s courses, I had the opportunity to improve my knowledge of chemical engineering with specific courses linked to the project aim and objectives, such as particulate solids processing and equipment selection, modeling and simulation of chemical processes, process optimization.

I am currently doing my internship and my Master thesis work at the Nestlé Research Centre (Société des Produits Nestlé S.A), in Lausanne, during which I am focusing on “multiscale models for the reconstitution of powders”. In detail, I will work on hybrid modelling approaches that will lead to time efficiency in the modelling process of my system of interest, by combining the data-driven modelling with the traditional mechanistic modelling.

[From 2021- 2023, Amine Ait Ouzzou worked on this project before taking up a role in industry]

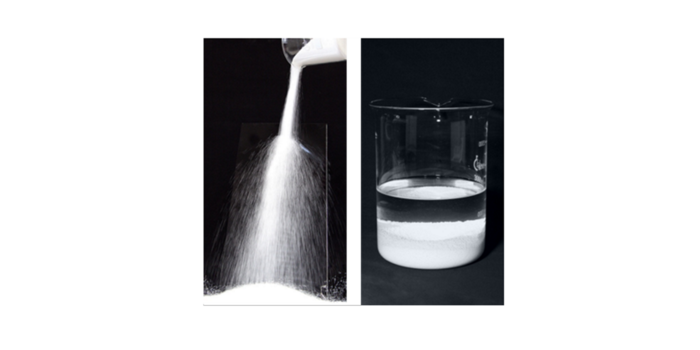

Compaction of powdered materials is typically performed to improve properties such as bulk density, flowability, dispersability, and stability. Using the knowledge gained through modelling and experiments these properties can be tuned by process to produce high-performance powders. A mesoscale model will be calibrated from the microscale model developed in TUSAIL and will be used for a PBM model, which takes into account all main particle properties, like size and size distribution, form, moisture, strength, rehydration and dissolution.

Amine Ait Ouazzou, Yogesh M. Harshe, Vincent Meunier, Jan Henrik Finke & Stefan Heinrich (2022), Influence of Process Parameters and Particle Size Distribution on Mechanical Properties of Tablets Chemie Ingenieur Technik, 95: 168-177. https://doi.org/10.1002/cite.202200157