Hamburg University of Technology [ 24 months ]

Process Systems Enterprise [ 12 months ]

Turn on Javascript!

Turn on Javascript!

Turn on Javascript!

Turn on Javascript!

I am Gero Stöckl, I am from Graz, Austria. I studied Chemical and Process Engineering at Graz University of Technology during my Bachelor’s and Master’s studies. In my Master’s thesis I investigate the use of deep neural networks for heat radiation modelling in polydisperse particle systems.

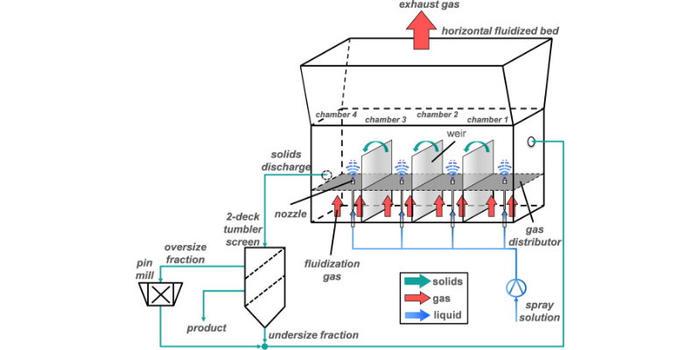

I am currently working as ESR 1 on DEM–CFD and PBM for dynamic process simulation of fluidized bed agglomeration at Hamburg University of Technology and later at Siemens Process Systems Enterprise. My supervisor is Prof. Stefan Heinrich. The aim of this project to develop a dynamic flow sheet simulation that can predict agglomeration in fluidized beds across different scales. This will be achieved by performing calibrated CFD-DEM simulations to study the particle and fluid behavior in fluidized beds. The results of these studies will then be used to inform a large scale PBM model, which will be validated with a pilot-scale fluidized bed. This will allow to predict agglomeration in fluidized beds at lab- and industrial-scale accurately.

Fluidized beds involve mass, momentum and heat transfer as well as two-phase flow. This project aims to develop an upscaling methodology using a multi-scale particle approach with coupled DEM–CFD simulations providing detailed particle-level information to inform a large-scale PBM model of full-scale fluidized bed agglomeration.

Gero Stoeckl, Aitor Atxutegi, Stefan Bellinghausen & Stefan Heinrich (2024), Employing a multi-resonance microwave sensor for in-line moisture monitoring of fluidized bed agglomeration Chemical Engineering Journal, 499; 156053. https://doi.org/10.1016/j.cej.2024.156053