Hamburg University of Technology [24 months]

Process Systems Enterprise [12 months]

Lorem ipsum dolor sit amet consectetur adipisicing elit. Quasi placeat perferendis iusto adipisci accusantium est rem eligendi possimus obcaecati doloribus voluptatum id libero ex, veniam unde necessitatibus optio quam cumque ut accusamus laboriosam mollitia consequatur ipsa! Vel et reiciendis, facilis dicta dignissimos pariatur? Doloremque nobis repudiandae labore laboriosam voluptatibus expedita necessitatibus mollitia, inventore officia illo, soluta ad aliquid similique. Consequuntur, dolorum! Exercitationem sunt nulla nihil quasi aspernatur saepe debitis iure perferendis consectetur, libero at molestiae in quis assumenda, eum amet sit reiciendis fugiat sint? Recusandae dolores mollitia culpa voluptatem corporis. Cumque consequatur impedit quidem deleniti, nemo magnam quis error alias? Consequatur nam quaerat laborum soluta necessitatibus tenetur molestiae alias quam quidem. Quibusdam officiis obcaecati fugiat quisquam, temporibus natus repellat ad porro nihil ea dolorem excepturi quod et doloribus autem praesentium delectus quam labore eligendi, aut iure est? Dicta optio nam fugiat rem similique earum, doloribus, eum ullam itaque quas suscipit?

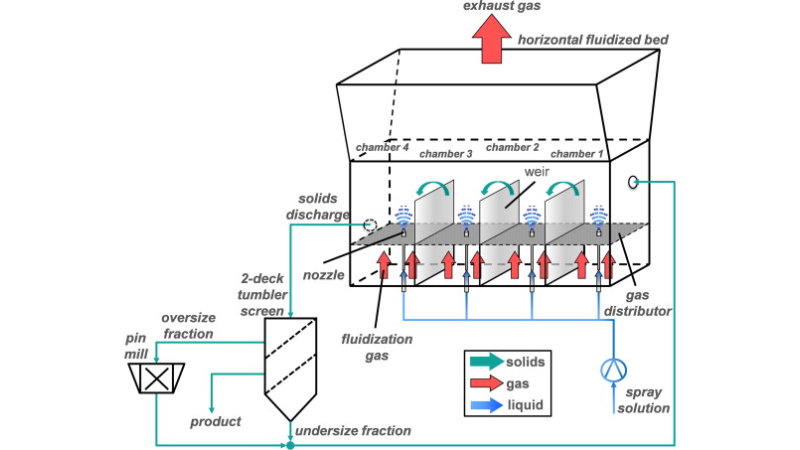

Fluidized beds involve mass, momentum and heat transfer as well as two-phase flow. This project aims to develop an upscaling methodology using a multi-scale particle approach with coupled DEM–CFD simulations providing detailed particle-level information to inform a large-scale PBM model of full-scale fluidized bed agglomeration.